This is how the new Audi Q8 e-tron is built

missing translation: fa.article-intro.reading-time – Copy: AUDI AG - Photo: AUDI AG – 05/17/2023

Only consumption and emission values according to WLTP and not according to NEDC are available for the vehicle.

The new, fully electric Audi Q8 e-tron models continue the success story of the electric pioneer Audi e-tron, which marked the beginning of Audi’s electric future in 2018.

The new, fully electric Audi Q8 e-tron models continue the success story of the electric pioneer Audi e-tron, which marked the beginning of Audi’s electric future in 2018.

When Audi’s first fully electric vehicles, the Audi e-tron and Audi e-tron Sportback, went into series production in 2018, it was the start of a new era at Audi’s Hungarian site in Györ. This is where the e-drives were produced and then delivered to Brussels, Belgium, for production of the Audi e-tron. And the same is true for the successor to the Audi e-tron, the new Audi Q8 e-tron.

Since 2018, Audi Hungary has become the centre of e-motor production in the Audi Group, and in the process the plant not only brought itself up to standard in terms of technology, but also set an example in terms of sustainability. Thanks to a geothermal plant, Europe’s largest rooftop photovoltaic system and other measures such as the purchase of biogas certificates, Audi Hungary has become carbon-neutral on the environmental balance sheet. A green production of the electric motors for the new Audi Q8 e-tron models is a substantial contribution to ensuring customers that the finished vehicles are also carbon-neutral on the environmental balance sheet. But it is not only the production of the e-drives that needs to be considered. Transport to Brussels also plays a role in carbon neutrality.

The road towards carbon-neutral production starts before the shipments leave the Györ site for the Brussels location. At the world’s largest engine plant, 97% of a total of approx. 5,000 components are delivered and stored in reusable packaging and special packaging materials to save resources during transport. In addition, more than 99% of waste created at the site of Audi Hungary is recycled. For transportation to Belgium, Audi uses eco-friendly rail transportation, the so-called “Green Trains” served by DB Cargo, which are either carbon-neutral or have a carbon-neutral balance sheet. When traveling through Austria, the trains are supplied with 100% green electricity from renewable energy sources thanks to “DBeco plus”. As this product is not available in Hungary and Belgium, Audi uses “DBeco neutral” in these countries instead. With this product, the power used for transportation is offset by means of climate certificates, reducing carbon emissions elsewhere and thus achieving carbon-neutrality on the environmental balance sheet for both production and transport of the electric motors from Györ to Brussels.

m²

on the roofs of Audi Hungary’s two logistics centres.

t

of carbon dioxide per year, which would otherwise be generated if fossil fuel power plants were used.

%

of its energy stems from renewable sources.

The Brussels plant is working on various levers to enable decarbonisation and was certified as the world’s first carbon-neutral large-scale production facility in the premium segment. As a matter of priority, Audi Brussels has achieved this goal using renewable energy based on three core pillars: at first, Audi switched to green electricity in 2012. To this end, one of the largest photovoltaic systems in the region was installed on the plant’s premises. It now measures 107,000 square meters and generates approx. 9,000 megawatt hours of electricity per year. Secondly, heat is supplied to the site (e.g. halls, offices, etc.) using renewable energy via coverage through biogas certificates. Water required for the heat supply is heated with gas compensated by biogas certificates. For each megawatt hour of gas consumed, a certificate of origin for one megawatt hour of biogas is purchased. Currently, the biogas comes from France.

Thus, 100% of the energy requirements at the Brussels plant are covered by renewable energy. The Brussels site offsets approx. 5% of technically unavoidable carbon emissions with so-called carbon credit projects as a third measure.

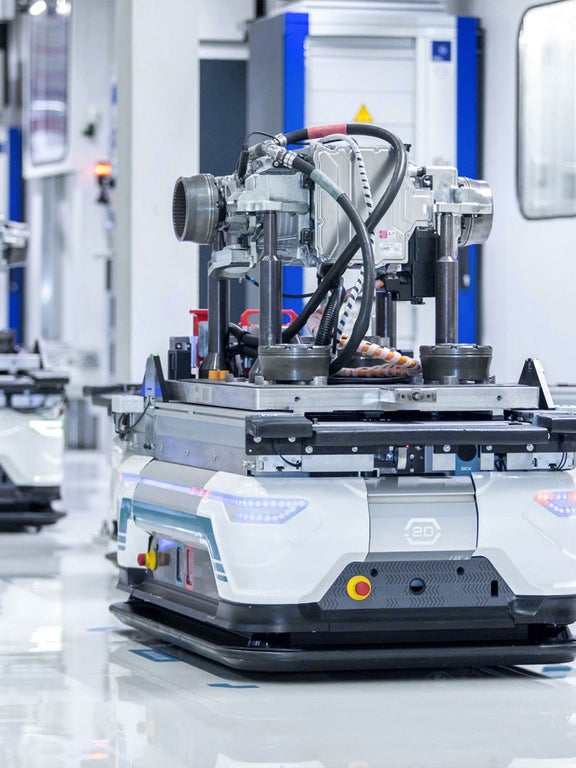

As the Brussels site is supplied with over 4,000 different parts and components from more than 500 supplier companies arriving by train and truck on a daily basis, Audi Brussels has set itself the goal of making infrastructural processes highly efficient, thus reducing energy requirements from the outset. To this end, the modern “Automotive Park” logistics and supplier centre provides the infrastructure for efficient material supply to the plant. It is connected to the production halls via a bridge. This close integration with smart in-plant logistics sustainably increases production efficiency as it operates with automated material transport using AGVs and digitised processes.

At the end of the production process, two sites and numerous departments (i.e. Production, Logistics, Sustainability, and Sales) have ensured that the production of the Audi Q8 e-tron can indeed be carbon neutral on the environmental balance sheet, making sure customers receive a fully green vehicle.